Topps Trading Card Print/Finishing Technologies

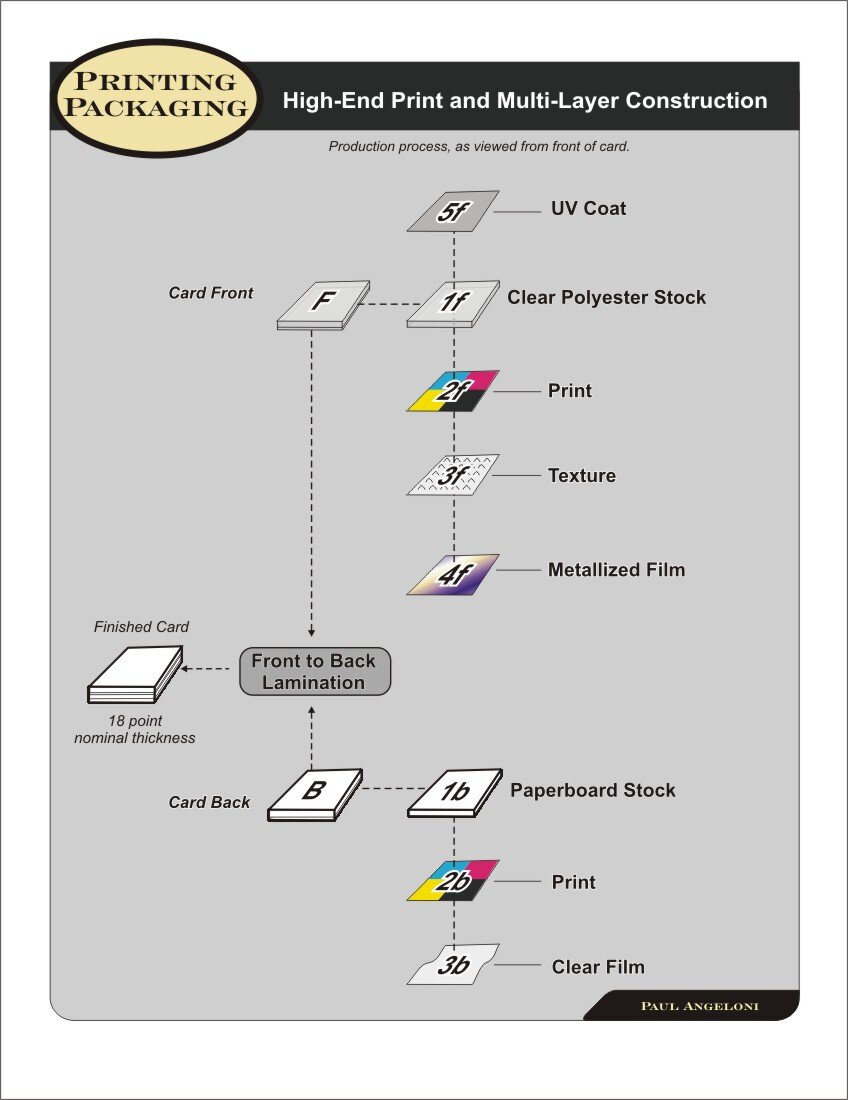

The remit was to develop print and finishing technologies that would not only leapfrog the trading card competition, but make Topps the leader in printing and finishing technologies, period. Within a few years, we had succeeded, and had gone from 4C printing on CCNB cardboard, to pushing the limits of conventional print and finishing and establishing a new paradigm for what a trading card could be.

This was accomplished by approaching the trading card as a 2.5” x 3.5” product, rather than a printed piece of cardboard. I expanded the stable of suppliers and technologies to include plastics, wood, metals, composites; micro-optics, electronics, lcd and enviro-active inks, security printing, complex multi-layer constructions, textural coatings, fabrics; and processes including: printing (all types), forming, stamping, laser cutting/engraving, embossing/debossing, coining, die-strike, casting, hydroforming, thermoforming, anodization, plating, holography (micro-etched and photopolymer)…and the list goes on.

We exploited nearly any and all industrial materials and processes into what a ‘card’ could be.