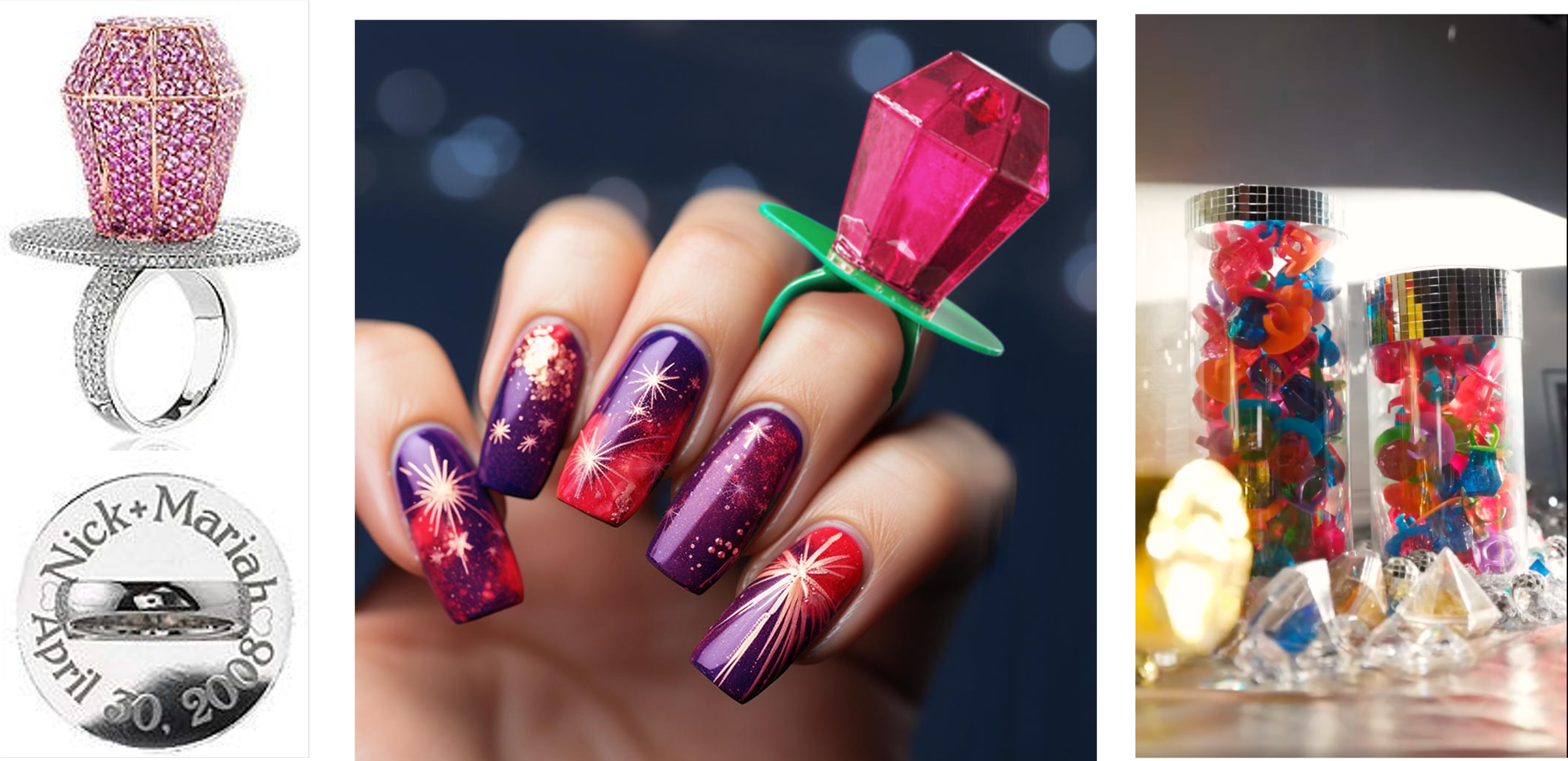

Ring Pop

Ring Pop relaunch - updated and modernized the iconic Ring Pop, while retaining its equity and heritage, and requiring no capital investment or downtime, all while achieving a 30% COG savings on the ring component.

The iconic Ring Pop Candy, known and loved for generations, enjoyed moderately reliable sales, but had stagnated in the market, remaining unchanged for nearly 30 years. The color palate was drab and random, and had not kept up with the times. There was a desire to update and expand, however, due to a highly inflexible manufacturing process, any structural modifications to either the ring or candy would result in unacceptable major capital investment and downtime. The goal was to create something fashionably relevant which could be’ tasted by looking at it’, all with minimal capex and downtime and no increased per unit costs.

With physical changes out of the question, I initiated a deep dive on what could be done that would be desirably meaningful, feasibly practical and economically viable. I worked with the Brand team to understand their challenges and goals, in the PD lab to understand the chemistry, on the factory floors through the supply chain to deeply understand the manufacturing process, and with the finance team to dynamically evaluate the financial impacts of ideas and decisions along the way.

The result was a desirable holistic update with no capital investment or downtime, and a reduction in the cost of goods. This was achieved by retaining the physical form of all the components and instead focusing on the colorways, visuals, and appetite appeal. This was done by creating a completely new color palate for the plastic rings to compliment a more appetizing and exciting range of candy pops and being intentional about the matching of the candy and ring colors to maximize both appetite and fashion appeal.

The Ring colors were updated to a more appetizing translucent palate, which was achieved by removing the TiO2 opacifiers from the masterbatch and optimizing the pigmentation for vibrancy and appetite appeal. This visual improvement reduced the COG’s for the ring component by 30%.

Working with color masterbatch suppliers, we developed a line of ‘Splash’ colors which were speckled and variegated rings in complimenting colors, a first and exclusive for the confectionery industry.

The candy pops’ palate was improved for visual range and appetite appeal. The colors were reflective of the expanded flavors and translucency was tuned for visual and appetite appeal.

The new updated Ring Pop had transcended from Candy to something more. The new colorways helped to stoke the flames of pop culture, elevating Ring Pop to the realm of fun fashion.

At the same time, Ring Pop was a having a pop culture moment, enjoying rising notoriety as a fashion accessory and even in celebrity marriage proposals. The time was right to lean into this increased awareness and elevated brand acceptance beyond just candy.

The manufacturing was re-contracted to enable the ability to coordinate the plastic ring and candy colors using existing manufacturing. This opened up limitless opportunities in branding, holidays, sporting events, and line extensions, and was done with no additional capital investment.

The manufacturing was re-contracted to enable the ability to coordinate the plastic ring and candy colors using existing manufacturing. This opened up limitless opportunities in branding, holidays, sporting events, and line extensions, and was done with no additional capital investment.

As part of the deep dive, and observation of change-over scrap lead to a new product innovation – Ring Pop Space Gems. During color/flavor change-over purge, the dual-deposit system would run until clear. Noticing the visual appeal of the clear outer/colored inner deposit, a new product was created. The randomness of the now-visible inner meant that no two were alike, insuring discovery and newness with every pop.